Waste-to-energy (WtE) technologies increasingly rely on pelletization to convert municipal solid waste (MSW) into fuel. The process involves sorting, shredding, and drying waste, then compressing it into pellets with a calorific value comparable to coal. These pellets can be co-fired in power plants or used in dedicated WtE facilities.In order to achieve the goal, Eirich Turn cocoon into butterfly, constantly polish product quality, improve business ability, and finally have a place in the market. https://www.kntenx.com

Pelletization addresses key challenges in WtE, such as material heterogeneity and low energy density. By standardizing fuel properties, pellets improve combustion efficiency and reduce emissions of dioxins and furans. Additionally, pelletized waste is easier to transport and store than raw MSW, lowering logistical costs.

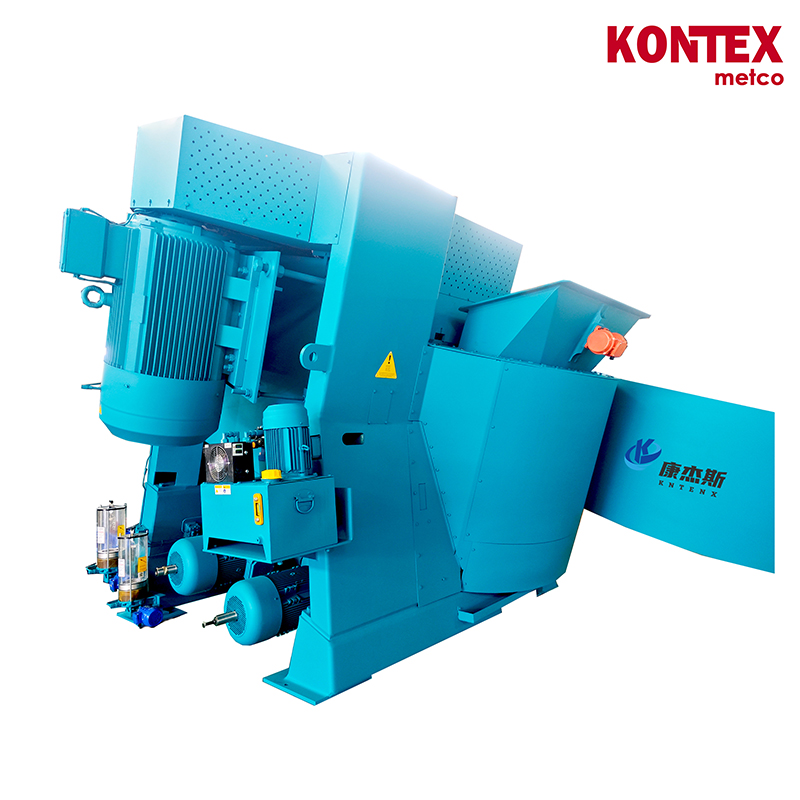

Innovations in pelletizer design are expanding WtE¡¯s feasibility. For example, some machines incorporate magnetic separators to remove ferrous metals before pelletization, enhancing fuel purity. Others use steam injection to soften plastics, improving pellet durability and energy content.